Necessity of wafer reliability test in vehicle specification SiC chip:

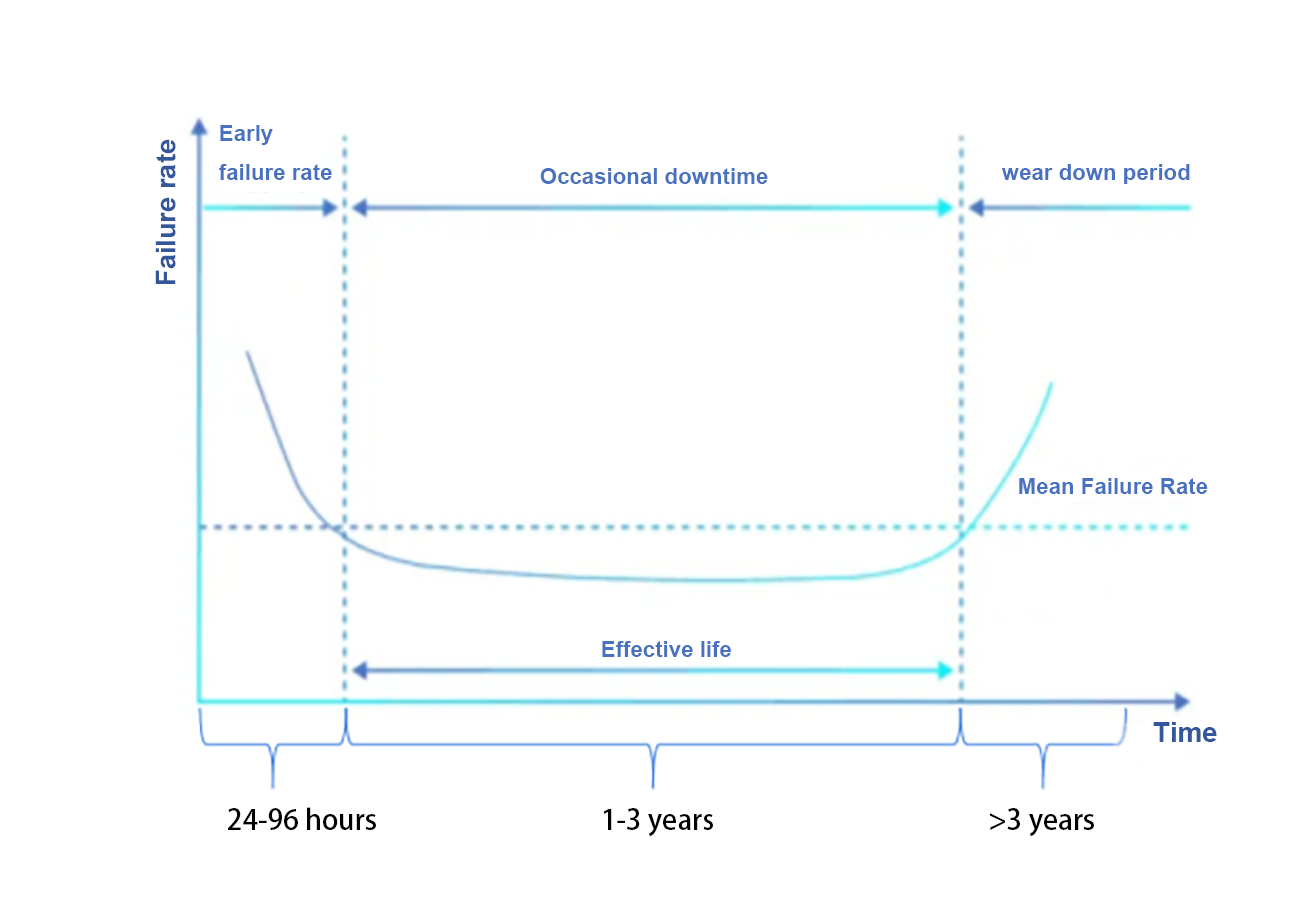

According to the bathtub curve theory, any electronic component will have a high failure rate at the beginning of its life cycle, and the failure rate will obviously drop to the stable period with the passage of time.

The SiC Power Module of the vehicle gauge is different from the ordinary to package device. There is only one die inside the ordinary to package device. If it fails, only a single device needs to be replaced. However, the SiC Power Module of the vehicle gauge protects dozens of dies. If one die fails, the performance of the whole module will be affected. Therefore, if bad dies can be screened out from the wafer in advance, the yield of packaged modules and the life cycle of modules can be greatly improved.

Nexustest provides a complete set of solutions for wafer aging, including CP loading machine wafer aging unloading machine KGD to solve the complete set of test solutions before packaging into modules.

Wafer Level Burn-In System: WLR3500

1、 Automatic Burn-In Switching: The system supports the automatic switching of GB and RB burn-in for up to six wafers simultaneously, significantly enhancing burn-in efficiency and convenience.

2、 Independent Temperature Control and Power Supply: Each drawer is equipped with its own temperature control and power supply system, ensuring precise and stable burn-in conditions for each wafer during the process.

3、 Wide Voltage Range: The system supports HTGB voltage of ±70V and HTRB voltage of less than 2000V, meeting the needs of various wafer burn-in tests.

4、 Multi-Channel Support: The entire system supports up to 4320 channels (720*6), achieving high parallelism in burn-in testing, which greatly enhances testing efficiency.

5、 High-Precision Testing: During the burn-in process, the system offers a leakage current resolution of up to 0.1nA, ensuring the accuracy and reliability of test results.

6、Hardware Circuit Protection: The system is equipped with comprehensive hardware circuit protection mechanisms to safeguard each circuit from overcurrent and overvoltage damage.

7、 Arching Protection: A high-reliability gas protection system with ~3 bar atmospheric pressure is provided, effectively preventing oxidation and arcing during the burn-in process.

8、 Real-Time Monitoring and Testing: Supports real-time monitoring of key parameters such as Igss (gate-source leakage current) and Idss (drain-source leakage current), and also supports Vth (threshold voltage) testing.

9、 Wide Temperature Range: The temperature control range extends from 40°C to 175°C, accommodating the temperature requirements for various wafer burn-in tests.

10、 Software Support: The software is user-friendly and features the test plan configuration for easy setup and adjustment based on user requirements. It also supports automatic Pass/Fail criteria, binning according to customer defined limits, and map data generation for data analysis and handling.